Approximately one year ago, a 71-year-old woman consulted Dr. Verstreken. She was suffering from chronic left wrist pain, caused by avascular necrosis of the scaphoid bone. Dr. Verstreken, a dedicated hand and wrist surgeon and a strong believer in the use of 3D technology in orthopaedics, treated the patient with an innovative solution: a custom made, 3D-printed scaphoid replacement.

Because standard prostheses for scaphoid replacement are rather rudimentary, and the results are often disappointing, a patient-specific implant could offer an attractive alternative. CADskills supports the development of ideas and the further implementation of a R&D strategy, so CADskills was the perfect partner for Dr. Verstreken.

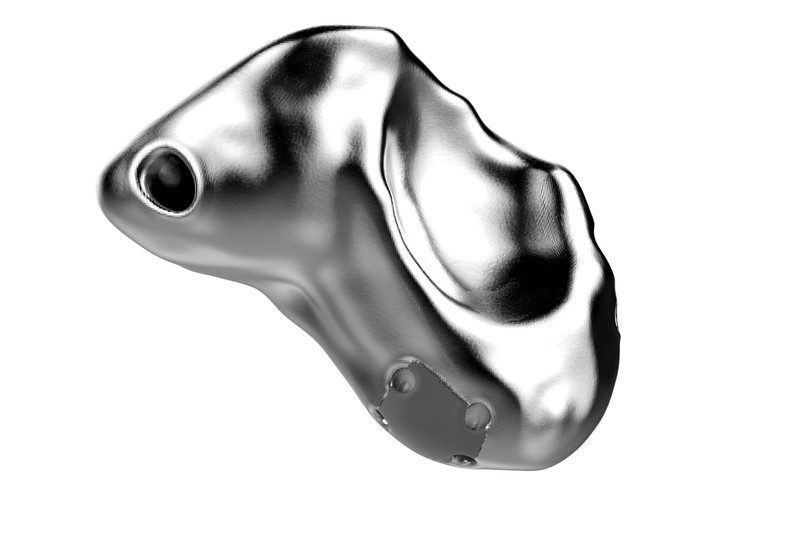

The necrotic scaphoid bone was removed and replaced by a custom-made scaphoid, the closest available for a "like-for-like" replacement. The design was based on the mirror image of the unaffected hand, resulting in a prosthesis with an anatomically perfect fit.

A number of features were implemented to ensure the best possible integration of the implant. Holes were incorporated to hold the implant in place using suture wire. Some surfaces were polished and some were roughened depending on the need for ligament apposition. Reconstruction of the scaphotrapezial and scapholunate ligaments, performed by suspension of a strip of the flexor carpi radialis tendon using a tunnel in the implant, was incorporated in later designs.

The surgical technique is shown in the images above.

The picture on the left is the result at 6-weeks post-operative. The scaphoid bone was centered in its correct anatomical position.

The 1-year follow up (pictured on the left) confirms that the scaphoid remained well aligned in its normal position.

The 3D-printed scaphoid functions in the proper physiological manner and restores wrist function. At one year postoperatively, she regained symmetrical range of motion and strength, compared to the unaffected wrist.